Congrats to Adult Education’s Industrial Maintenance Grads

Congratulations to the 2023 Adult Education Industrial Maintenance Graduates—Owen Blanton, Dillion Brown, Justin Campbell, Charles Curren, Tammie Dial, Kelly Keller, Joshua Kirk, Moe Min Win, Jarrid Miracle. Not pictured: Ethan Hollenbaugh, Wesley Troutman and John Webber. You are ready to work with almost a year’s worth if training.

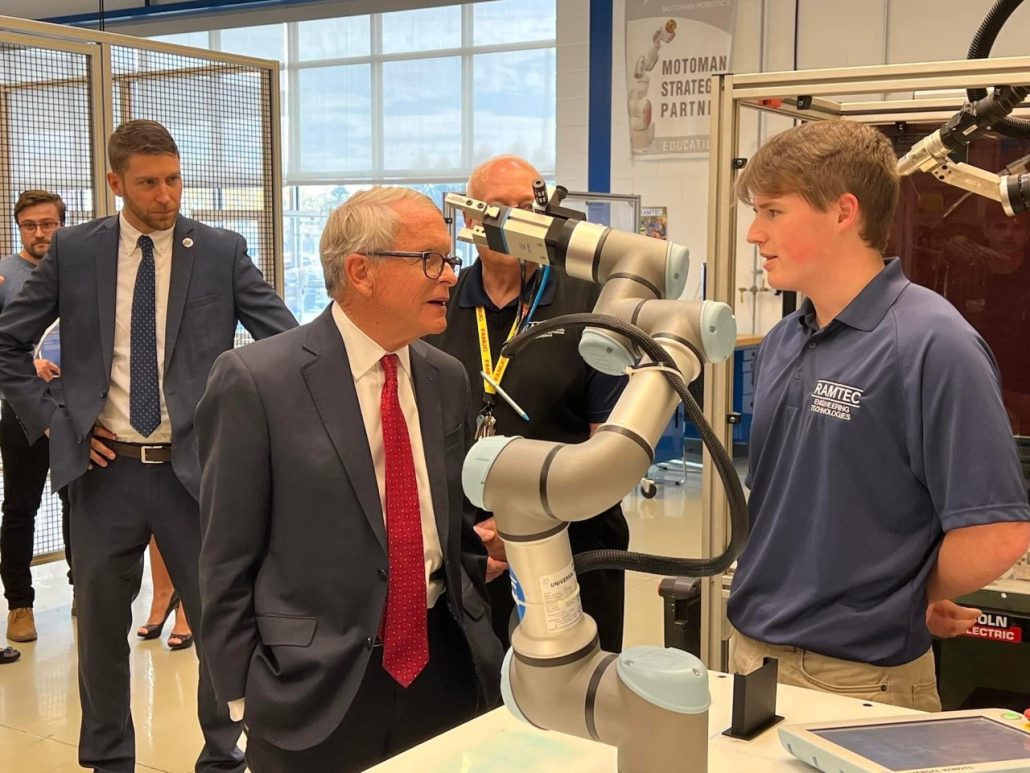

The Industrial Maintenance Training Program at Tri-Rivers provides the skills necessary to perform industrial maintenance tasks in today’s manufacturing operations.

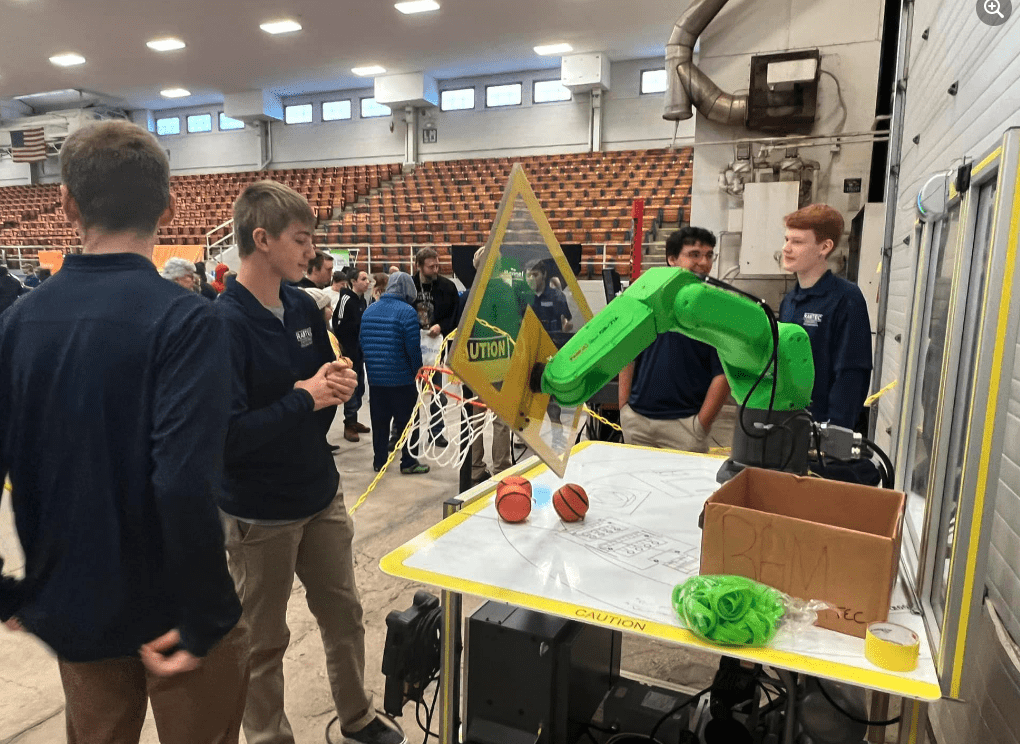

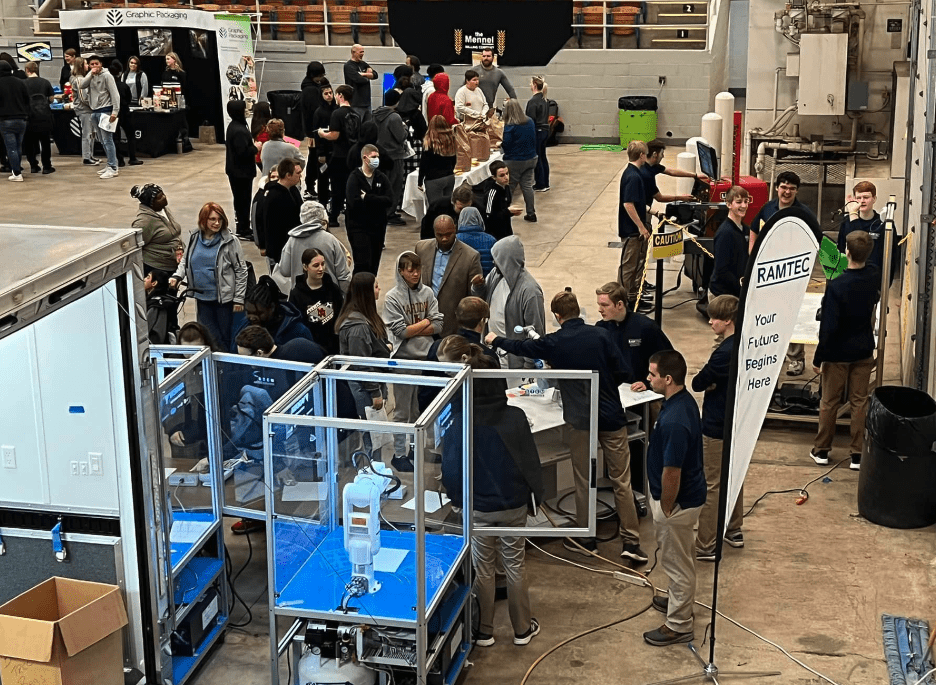

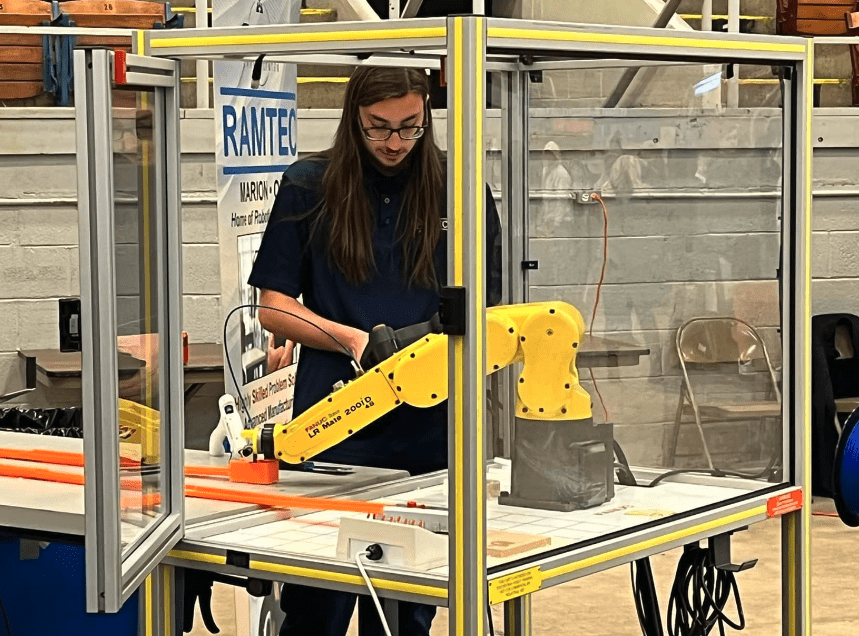

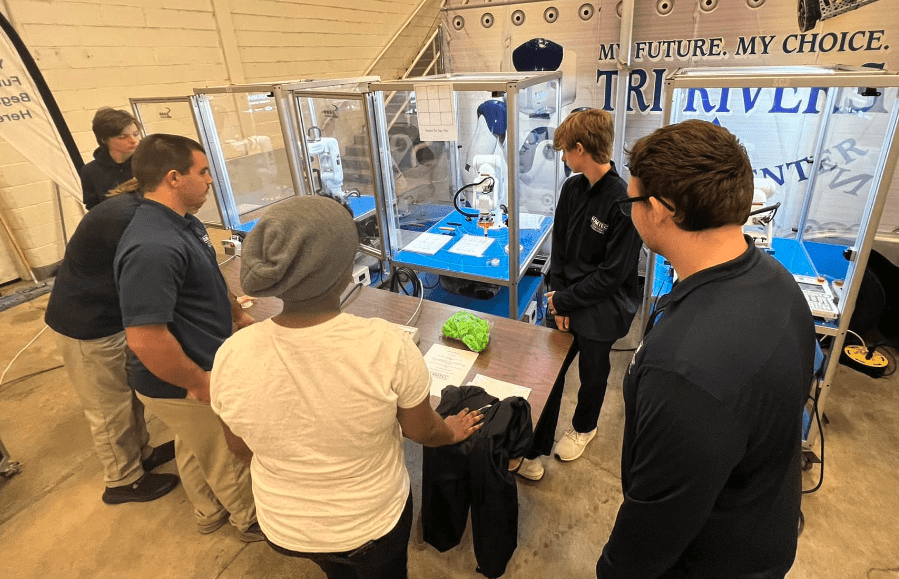

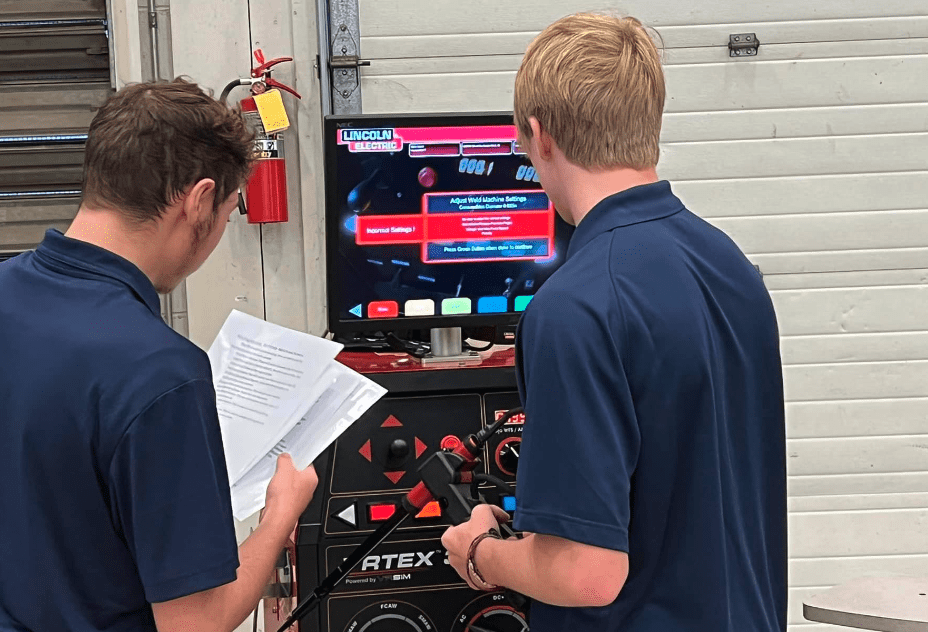

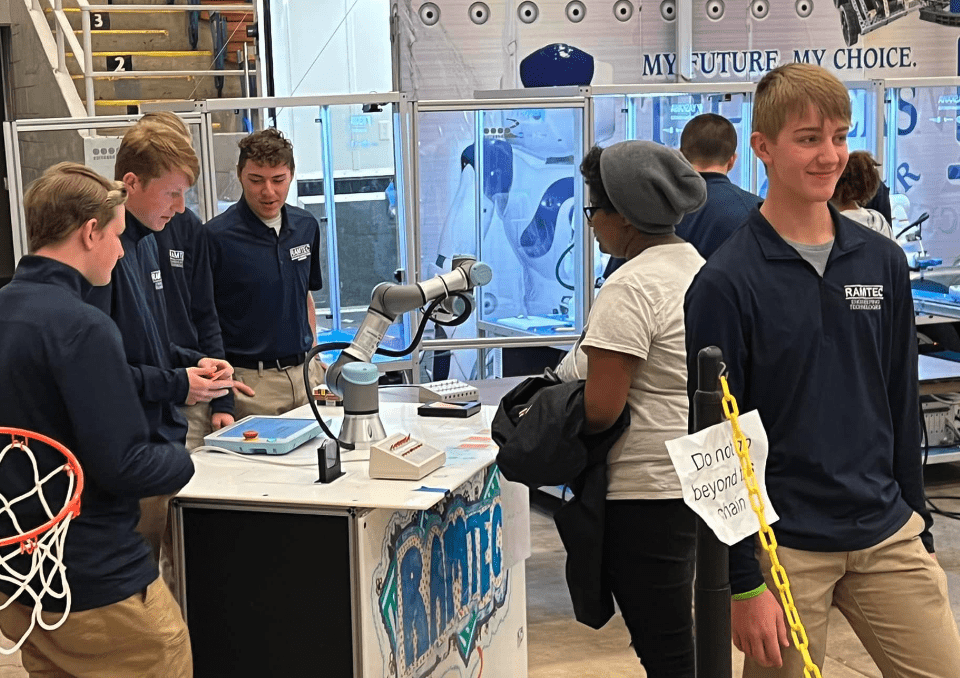

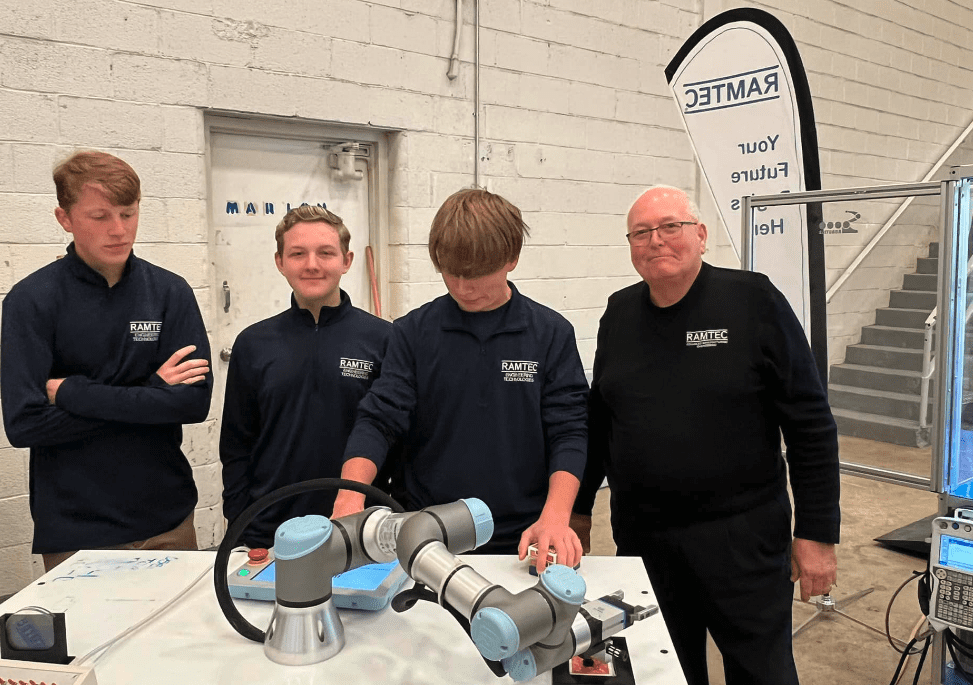

This is a complete curriculum. Our professional instructors give you hands-on training in each of our classes—Intro to Robotics, Basic Welding, Advanced Welding, HVAC training, Basic Electricity and Electronics, Introduction to Computers and Hydraulics, Pneumatics, PLC’s, Machine Tools and more. We’ll give you the knowledge and skills to get you prepared for the 21st century.

You’ll do more than read a textbook. You will design, build, test and troubleshoot. You’ll demonstrate your knowledge. Be prepared to learn!

Click Here for program details.

If you live in central Ohio and want hands-on learning—Come to Tri-Rivers!